Description:

9 Dekalb Ave. is a high-rise structure that will rise 1,066 feet and 73 stories, becoming the tallest building in Brooklyn. The luxurious skyscraper designed by SHoP Architects and developed by JDS Development is planned to have over 500 residential units, including commercial space.

The supertall edifice will join the landmarked Dime Savings Bank, a historical and monumental building founded in 1859 which will be restored to connect pedestrians between Flatbush Avenue and Fulton Street. 9 Dekalb Avenue will add a glamorous look to Downtown-Brooklyn due to the use of marble and bronze as the primary materials of the construction.

The tower’s location offers a wide variety of trains and bus lines to commute in the city. It is also close to malls, stores, Michelin-starred restaurants, gyms, and parks. Downtown Brooklyn features arts and culture events offered by the Brooklyn Cultural District. The busy neighborhood resembles the awakening energy of New York City.

ULMA Solution:

The complexity of 9 Dekalb Avenue required ULMA to provide forming, shoring, climbing, and safety solutions to build the foundation and raise the robust and intricate structure.

ULMA’s lightweight handset panel MEGALITE is currently being used to erect the walls and columns of the tower. This product supports a concrete pressure of 1,250 psf and allows the erection of walls higher than 8’. Right now, MEGALITE is present all over the base structure of the building while the first columns are being built. At the same time, our H20 beam slab formwork ENKOFLEX is used to form slabs with a thickness of 12 inches. The system is supported by ALUPROP posts. The aluminum shoring posts are the perfect solution to shore horizontal formwork. The props have a high load-bearing capacity, and they are easy and quick to adjust and enable ergonomic and safe working conditions for workers.

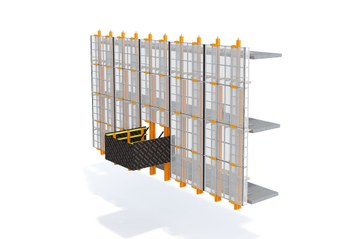

ULMA is committed to reflecting safety in the design of its systems. We promote worker safety by providing solutions such as our newly improved telescopic HWS perimeter safety screens. HWS is specially designed for high-rise buildings like 9 Dekalb. The exceptional height and constant change in the shape of the building required this technical solution. The other big challenge of this job was the transfer levels. These are high floors in which the perimeter of the building is made of solid walls. 9 Dekalb has three transfer levels, 34th Floor (32’ tall), 51st Floor (24’ tall), and 74th Floor (24’). Our HWS system has been designed to provide bracing to the walls forming prior to pouring and to be able to climb through them hydraulically, avoiding the customer the need to use the crane. This self-climbing system protects workers from harsh weather and from them or any object to fall from the edge of the slabs.

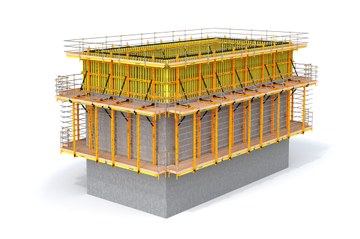

For panel climbing and safe lifting operations, Rail Climbing Formwork RKS will be used. This system ensures safe climbing at height due to the rails attached to the walls. It is versatile and can be lifted by a hydraulic mechanism or without crane assistance.