Description

Located between Cambridge and Kitchener in Ontario, the Roseville Road Overpass is a vital transportation link crossing Highway 401 — the busiest highway in North America.

The Ministry of Transportation of Ontario (MTO) initiated this project to replace the existing bridge with a new 120-metre-long structure, designed to accommodate future highway widening and upgrades.

The new bridge is a 1.9-metre-deep, post-tensioned cast-in-place concrete girder with a service opening to facilitate future inspections and maintenance. Maintaining uninterrupted traffic flow on Highway 401 during construction was a primary requirement, demanding precision engineering and reliable shoring and formwork solutions.

ULMA Solution

ULMA Construction in Canada provided a complete engineered formwork and shoring solution and service that ensured structural integrity, construction efficiency, and both worker and driver safety throughout the project.

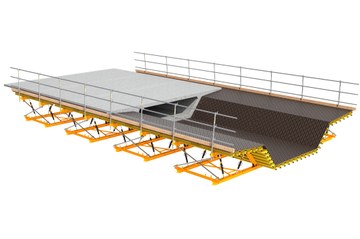

The systems supplied included ENKOFORM HMK Bridge Formwork, MK-360 High-Capacity Shoring Towers, and ALUPROP Shoring Towers — all designed, preassembled, and optimized to meet the specific technical and logistical demands of the project.

- 90% of the bridge formwork was preassembled at ULMA’s yard and delivered to the jobsite as ready-to-use formwork panels, minimizing on-site labour and assembly time.

- All the geometry details of the concrete formwork were designed using the standard elements of the ENKOFORM HMK Bridge Formwork product family, ensuring adaptability and cost efficiency.

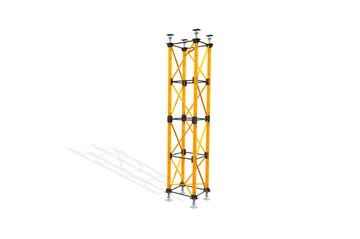

MK-360 High-Capacity Shoring Towers:

- The design required two separate openings with 15-meter-long spans under the formwork, to allow for continuous traffic flow below in both directions of Highway 401.

- MK-360 shoring system was designed and used to carry the weight of the concrete, formwork, the concrete finisher machine, and the working load on the platforms.

- Half of the shoring was preassembled and delivered to the jobsite as ready-to-use high-capacity shoring towers.

- Despite severe weather conditions, including a thunderstorm with wind speeds up to 90 km/h during the construction period, the MK-360 shoring system was used without any problems as a result of the detailed engineering calculations and design.

- The geotechnical design of the soil benching at both ends of the bridge required variable heights of shoring towers. The prop height range of ALUPROP system from 35 cm to 6 meters was used to accommodate the required geometry.

- The formwork and shoring for the 1.3 meters high service opening in the bridge cross section had to be designed for the whole length of the bridge. This was supported by connecting 35 cm high ALUPROP spindles together.

- The Bracing Frames of the ALUPROP system were used to create platforms for post tension works at pier locations without needing an additional scaffolding.

- The weight of the concrete finisher machine was also carried by the ALUPROP shoring system.

- Despite having a thunderstorm with 90 km/h wind speeds during the construction period, the ALUPROP shoring system was used without any problems, a testament to ULMA’s robust engineering and detailed structural analysis.

Project Features

- 120-metre-long post-tensioned concrete bridge structure.

- Continuous traffic maintained on Highway 401 during construction.

- Modular preassembly of formwork and shoring for rapid on-site installation.

- Engineering design accounted for high wind loads and variable soil conditions.

- Collaboration with the Ministry of Transportation Ontario and project contractors to ensure safety and reliability.