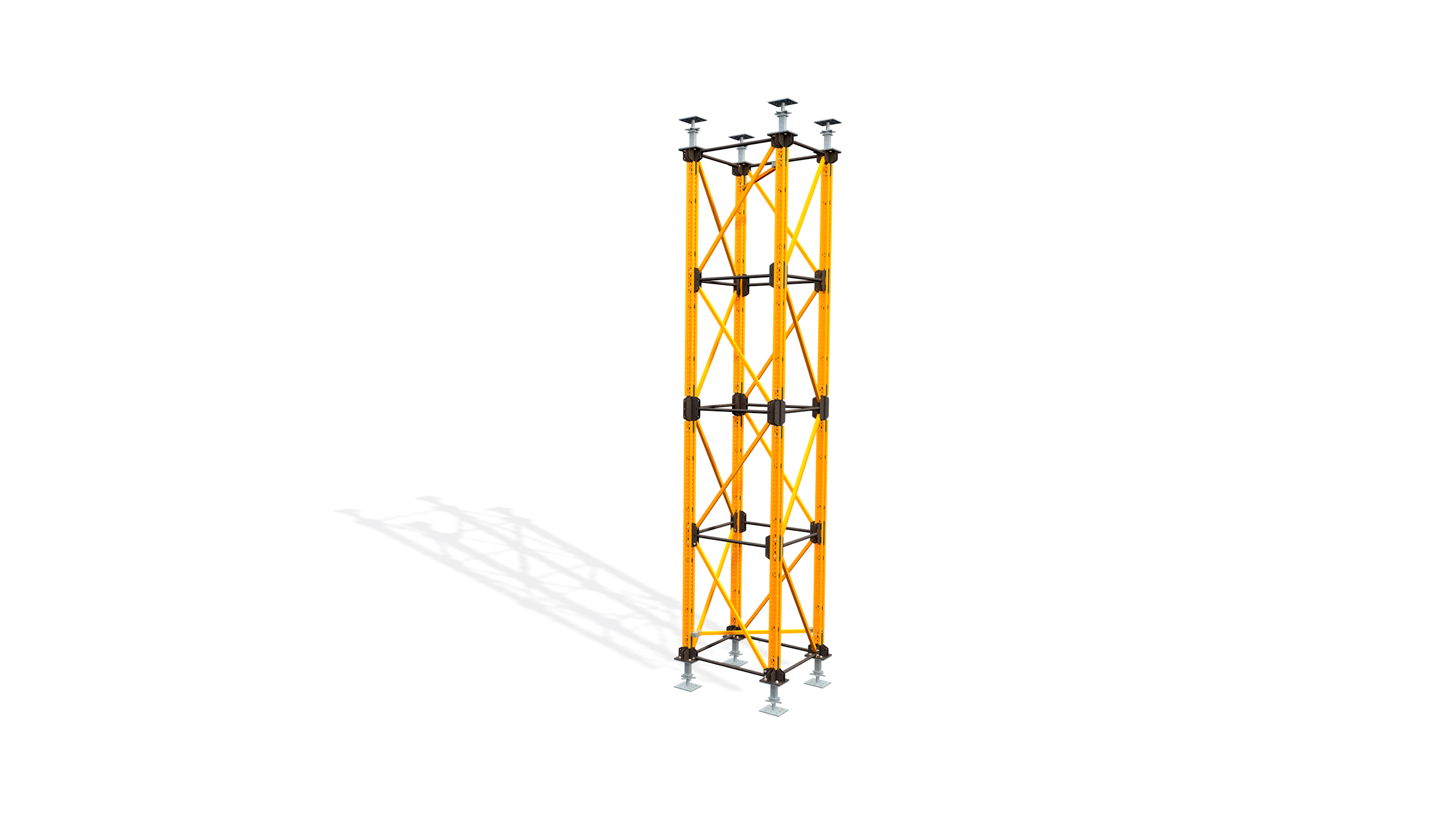

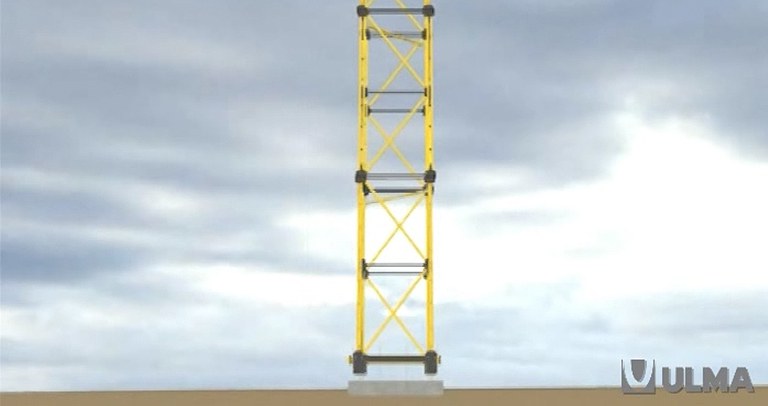

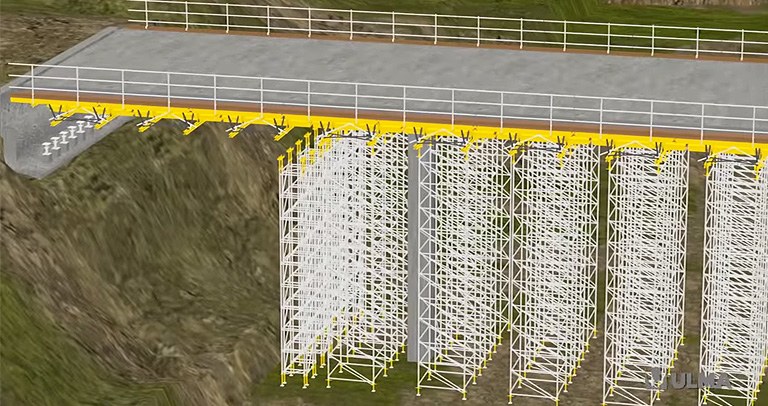

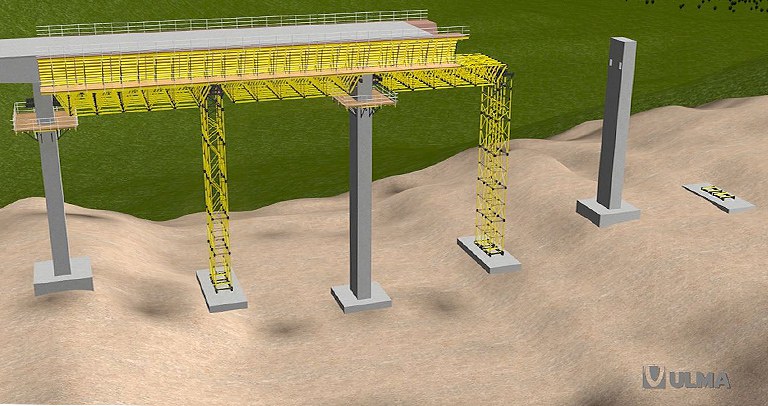

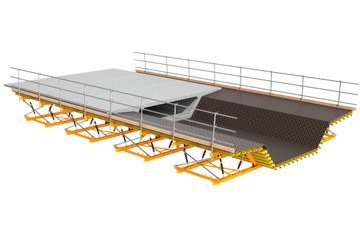

MK shoring towers are structures for heavy loads, mainly used in the civil engineering sector. Based on the MK system, it is a modular and flexible shoring tower that offers multiple shoring configurations.

MK shoring system guarantees on-site safety at all times thanks to the platforms, handrails and stairs that can be installed anywhere on the load-bearing tower.

- The module sizes in plan view are 0.75 m; 1 m; 1.5 m; 2 m; 2.5 m and 3 m (in all their combinations).

- Possible shoring configurations:

- MK-360 shoring tower: heavy duty shoring tower, around 250-360 kN per foot. Optimised for gantry shoring applications system, is used for large load truss support as well as for heavy steel profile support.

- MK-150 shoring tower: load-bearing capacity of around 100-150 kN per foot. This shoring tower is more simple than the MK-360 and is mainly used for low shoring of beams and slabs, prefabricated beams and for on-site steps combined with other types of shoring.

- MK prop: based on elements of the MK-360 and MK-150 shoring towers. The load limits of this prop are determined by the buckling of the MK waler and the anchorage conditions at the base. It is mainly used for supporting beams and slabs in abutment zones, as well as cases where the support area at the base is too small for a tower.

- Quick and safe on-site erection.

- Very versatile modular system for different shoring configurations.

- Erection as independent or chain-linked towers.

- Few elements for an enormous variety of combinations.

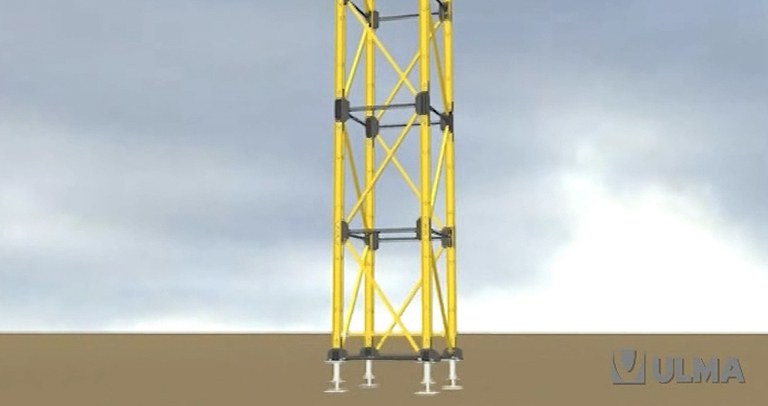

- Independent jacks for superelevations.

- Easy and secure joints between components.

- Tower base can be anchored to the ground for increased load capacity.

- Different stripping options at base or head:

- Stripping with hydraulic jack at base and head.

- Stripping with wedge at base and head.

- Stripping with jacks at head.

- Wind bracing systems can be used to join MK towers optimising the solution.

- Ensured safety: platform and handrails at any point of the towers. Access ladders between towers.